Extraction & Purification Service

There are all kinds of materials that are beneficial to our body in the food that we eat every day, and we call them active ingredients. Through the technology of extraction and purification, we can extract these ingredients from the food that we eat, and turn them into nutraceuticals, or develop new drugs that keep people healthy.

The Aquavan Group has more than 2 decades of experience in extraction and purification. We can identify the active ingredient within a material and develop the know-how to produce highly-concentrated, mass-production grade extraction in a couple of months. We work with thousands of partners to provide exceptional extraction and purification services to our customers.

The Aquavan Group has more than 2 decades of experience in extraction and purification. We can identify the active ingredient within a material and develop the know-how to produce highly-concentrated, mass-production grade extraction in a couple of months. We work with thousands of partners to provide exceptional extraction and purification services to our customers.

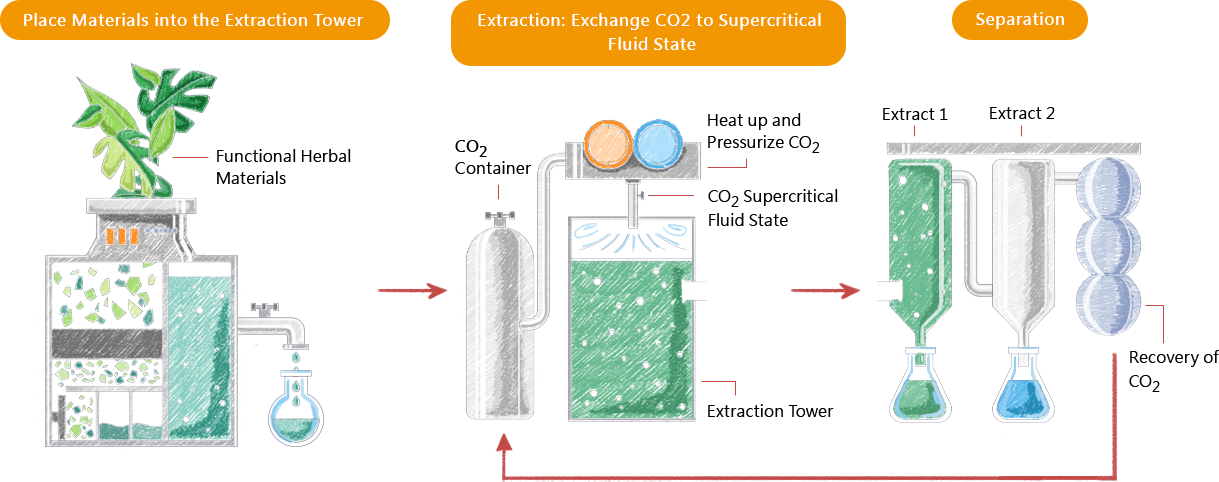

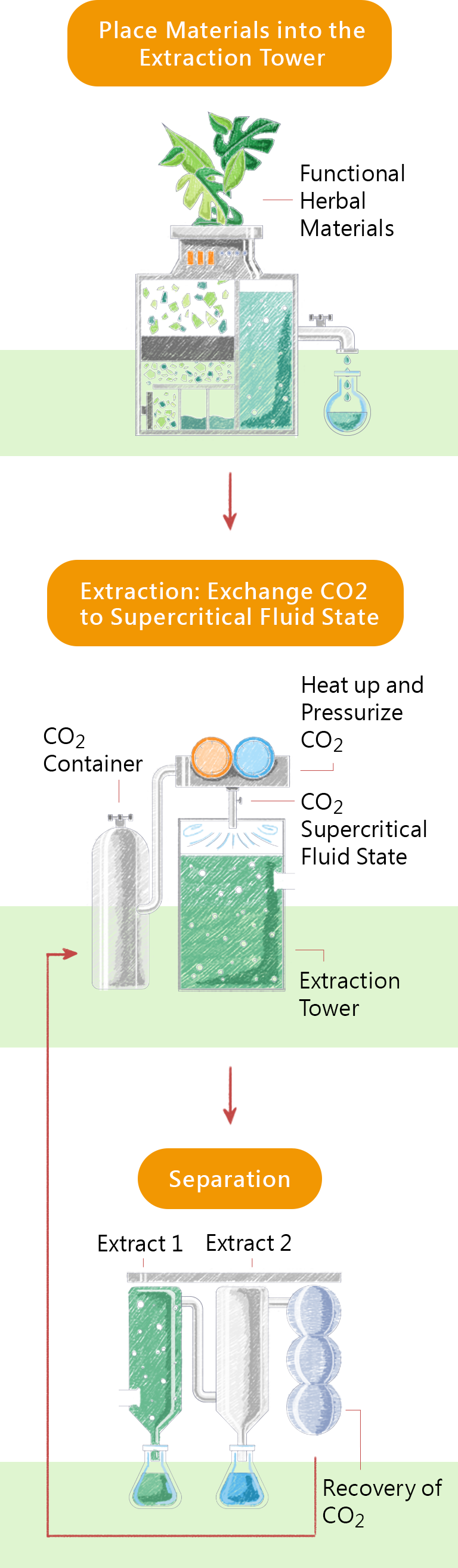

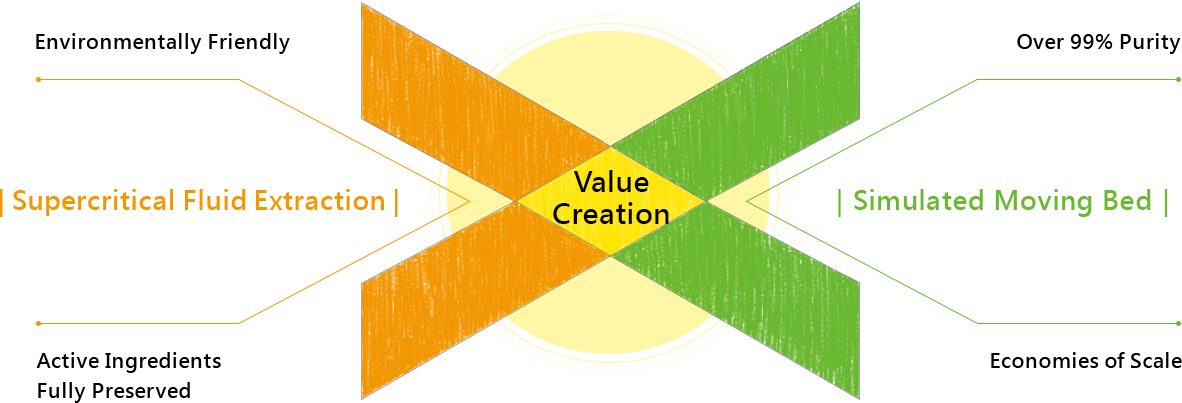

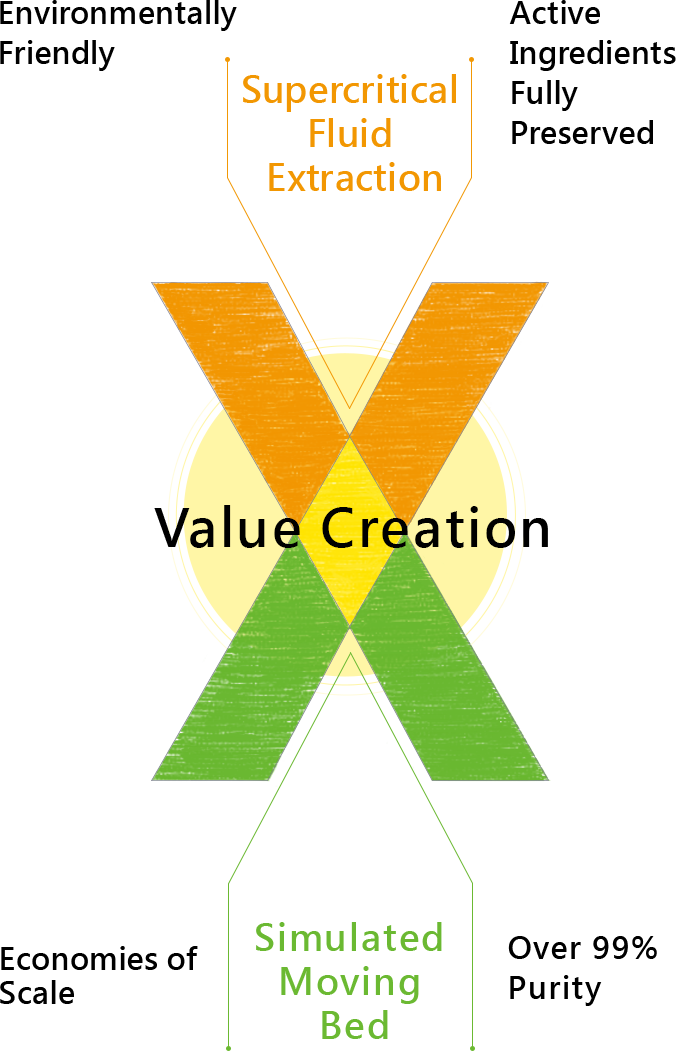

Supercritical Fluid Extraction

Supercritical fluid extraction technology is a low-temperature, high-pressure, oxygen-free extraction technology that uses supercritical fluid to obtain the required active ingredients.

In the extraction process, we use carbon dioxide as the supercritical fluid. The critical temperature of carbon dioxide (31℃) is close to room temperature, and as a result, deals minimal damage to active substances while being safe and non-toxic. The extraction and separation can be completed in one procedure with no residue. It is the most suitable supercritical fluid for the extraction of active ingredients that are beneficial to the human body.

In the extraction process, we use carbon dioxide as the supercritical fluid. The critical temperature of carbon dioxide (31℃) is close to room temperature, and as a result, deals minimal damage to active substances while being safe and non-toxic. The extraction and separation can be completed in one procedure with no residue. It is the most suitable supercritical fluid for the extraction of active ingredients that are beneficial to the human body.

Simulated Moving Bed Purification Technology

Chromatography is a technique for the separation of a mixture and is widely practiced in different chemical fields. The mixture is dissolved in a fluid called the mobile phase, which carries it through a column holding another material called the stationary phase. The different partition coefficient of the various constituents in the mixture results in differential retention on the stationary phase, causing them to separate. However, when it comes to mass production, several drawbacks with this technique raises cost significantly.

In the Aquavan Group we use Simulated Moving Bed technology (SMB). By altering the arrangement of the columns, we lengthened the stationary phase indefinitely, and allow the feed entry and analyte recovery to function simultaneously and continuously. With this technology, we can greatly reduce the cost and achieve economical mass production.

In the Aquavan Group we use Simulated Moving Bed technology (SMB). By altering the arrangement of the columns, we lengthened the stationary phase indefinitely, and allow the feed entry and analyte recovery to function simultaneously and continuously. With this technology, we can greatly reduce the cost and achieve economical mass production.

Extraction & Purification Service

Developed Technology

- EPA purification

- Trehalose extraction and purification

- Schisandra lignin purification

- Luteolin purification

- Tanshinone IIA purification

- Dendrobium nobile purification

- Antrodia cinnamomea triterpenoids purification

- Capsaicin purification

- Resveratrol purification

- Emodin extraction and purification

- Gossypol purification

- Oligosaccharides extraction and purification

- Astaxanthin extraction and purification

- Bamboo leaf flavonoids purification

- Curcuma extraction and purification

- Saffron extraction

- Bitter gourd triterpenoids purification

- CLN purification

- Petunidin purification

- Lutein purification

- Sesame purification

- African cardamom purification

- Betulin purification